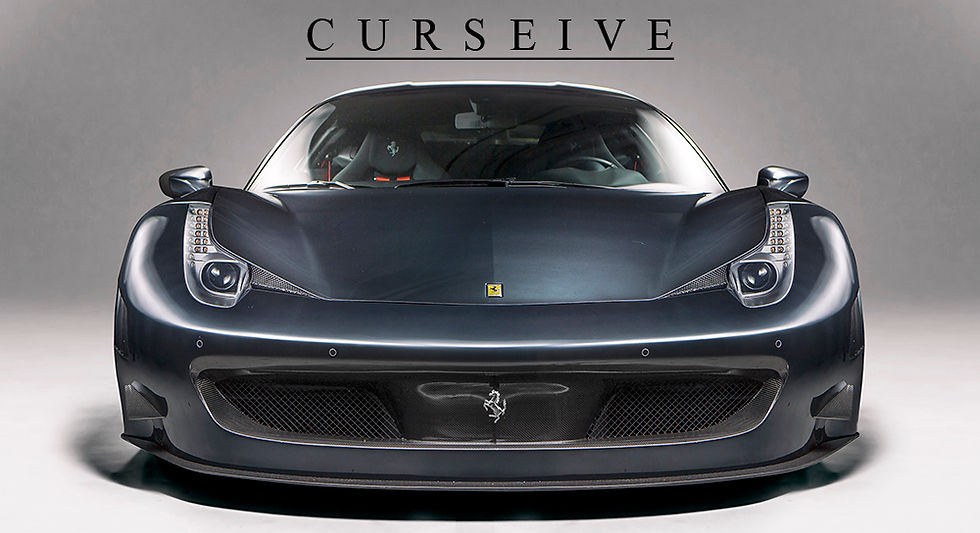

Creative design and composite manufacturing

We create your vision in composite

All parts are developed and tested to their limit before being offered for sale to trade and public.

Creative design and composite manufacturing

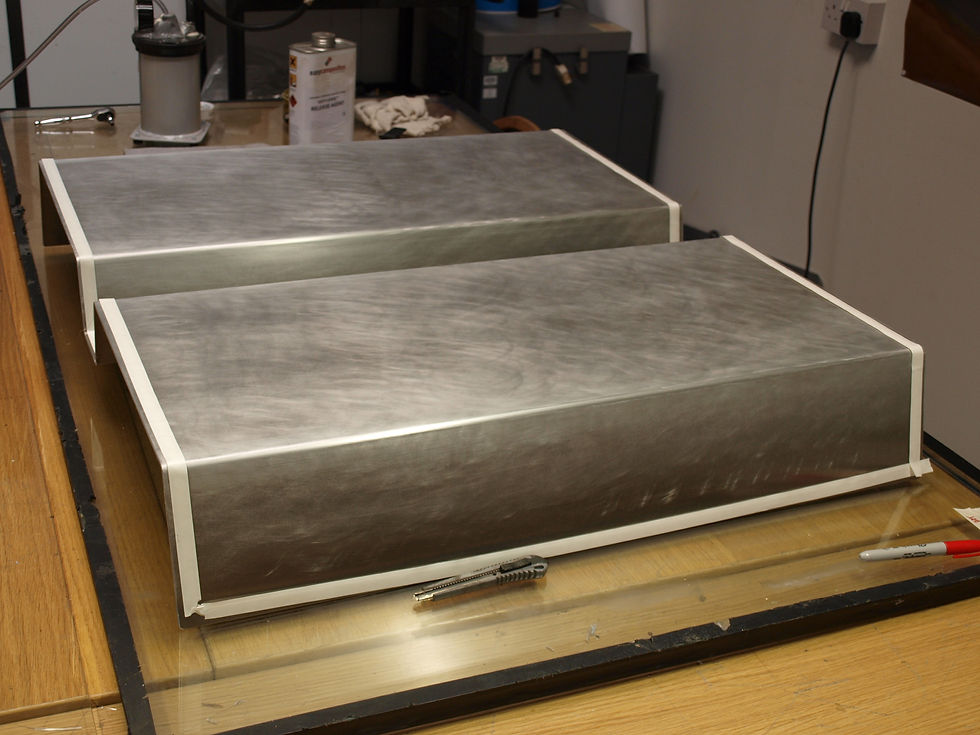

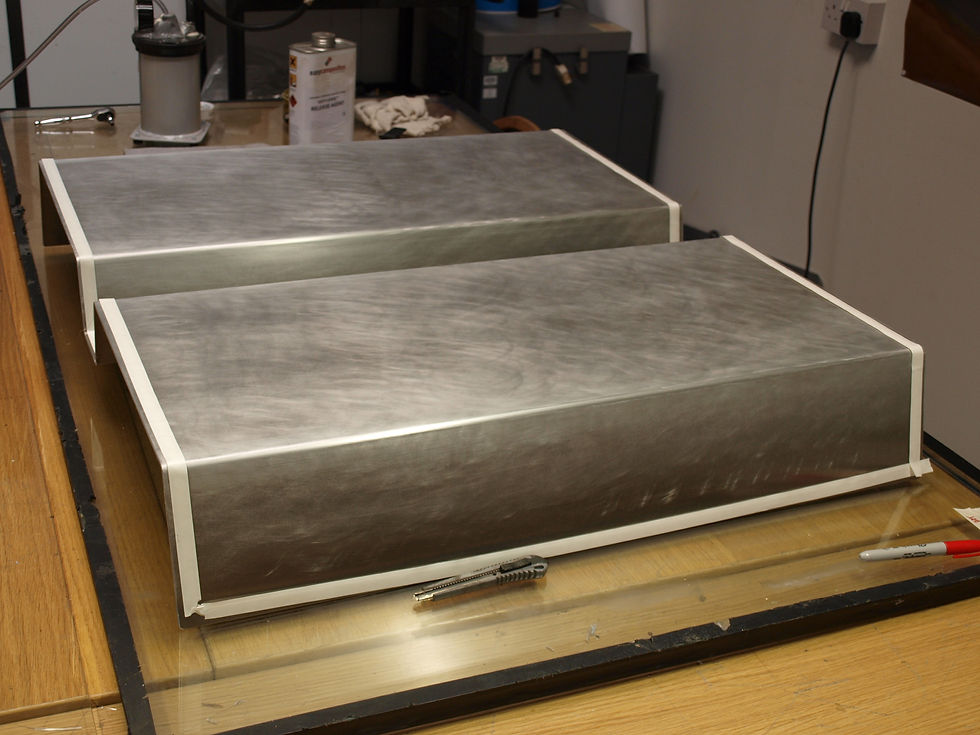

We offer Resin infusion and out of autoclave prepreg process's, as well as low volume mould making and manufacturing service.

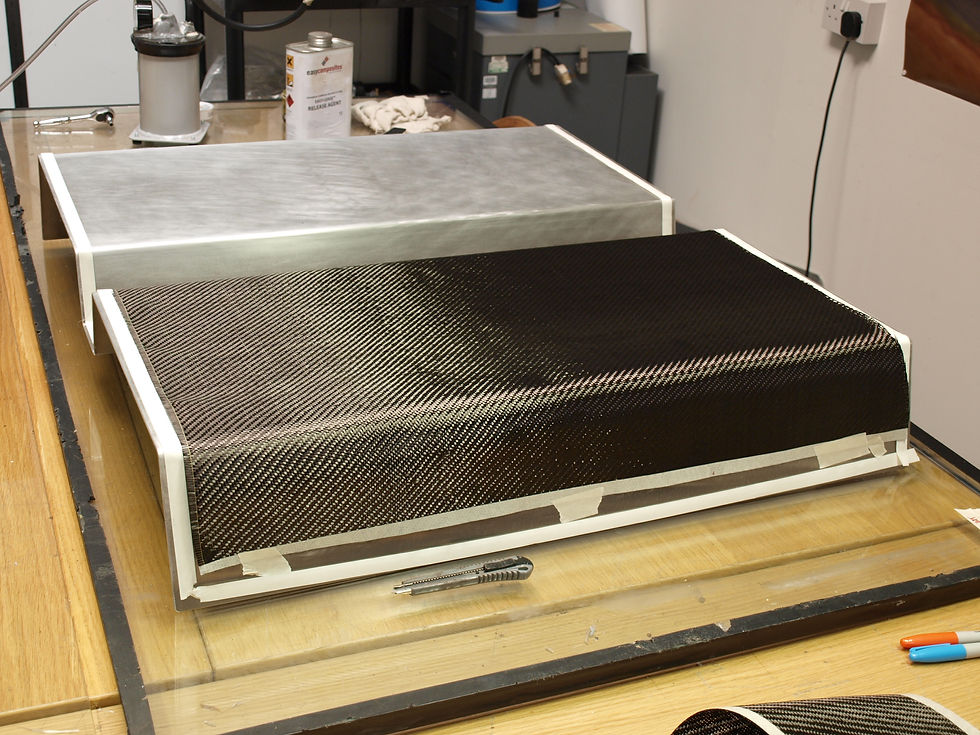

Specialising in resin infusion or Resin transfer moulding allows us to offer a high quality product without the high costs of Prepreg for things like Carbon fibre composites. This process is perfect for non mechanical composite parts and can be scaled for large and small product manufacturing. We can cater for the motorsport industry as well as the luxury car aftermarket, whether you require glossy seamless carbon or ultra lightweight composite structures, we are the right choice for your composite needs.

Race car specialists, race car builders, custom car builders, composite fabrication, composite manufacturer, carbon fibre specialist, resin infusion specialists

We manufacture high quality replacement parts or offer a repair service using our own moulds and repair tooling in order to insure a perfect finish.

We have a large portfolio and experience in composite repairs, giving new life to expensive parts and products that otherwise would be replaced. Please feel free to contact us with any questions or queries regarding any composite repairs large or small.

Whether you have light bodywork damage or require a complete rebuild, our composite department sits alongside our workshop with extensive tooling and expertise we complete repairs from all manor of incidents large or small.

We manufacture high quality replacement parts or offer a repair service using our own moulds and repair tooling in order to insure a perfect finish.

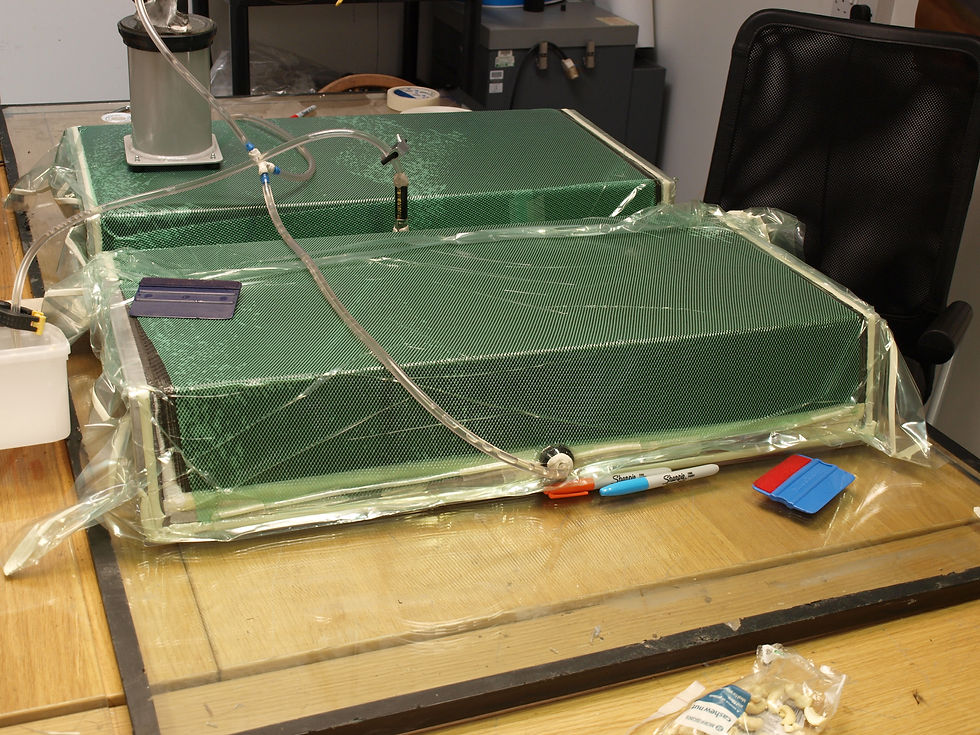

Resin infusion is an environmentally friendly alternative to open moulding. Resin infusion produces consistent, high-quality parts for products of all sizes, from small air scoops to pleasure boats.

The process impregnates layers of dry reinforcement (e.g. carbon fibre) between a rigid, air-tight mould and a flexible sheet sealed to it around its perimeter. A vacuum is applied to the mould cavity before resin is allowed to infuse into the reinforcement under atmospheric pressure, impregnating both across and down through the reinforcement layers without allowing air into the impregnation. This results in a product that has an excellent resin to reinforcement ratio, and therefore lightweight, strong, beautiful products.